Material Fabrication Processes in addition to Equipment for Production of High Performance Products

Metal fabrication refers to the means of combined operations used to make something out of metal. The particular equipment accustomed to conduct the operations will be: metal shears, laserlight cutting machines, water-jets, turret punches, engineering centers, press brakes, rollers, and welded machines. By far the most commonly used types regarding metals are co2 steel, stainless metal, and aluminum. Many metal fabricators buy metal in the forms of sheet, tavern, and tubing to begin the fabrication method.

Metal sheets are employed as a beginning basis for some sort of very large variety of metal products and even can be bought in a selection of gauges or even thicknesses. When typically the thickness of the particular sheet is 3/16" or greater, that is then known "plate". Sheets will be fabricated into a huge number of different types regarding items like commercial machinery, augers, conveyors, electronic enclosures, brackets, machine components, home appliances, food processing gear, just to label a few.

The particular first technique of linen metal fabrication will be often to possibly shear, laser trim, or punch shapes with it. The equipment used to execute these steps will be a metal shear, a laser, in addition to a turret punch. Sometimes all 3 of such operations may well be used as the metal is nonetheless within a flat condition. As soon as the basic level shape is achieved, the metal goes to the hit brake machines to be able to make the bends. This procedure is called developing. Dies in a variety of forms are utilized in typically the press brake in order to make one bend over or a series of bends to form the metal as specified on the prints. At this kind of point, some tasks may be complete and can then be shipped in order to its end work with, but often it goes to the welded tables next.

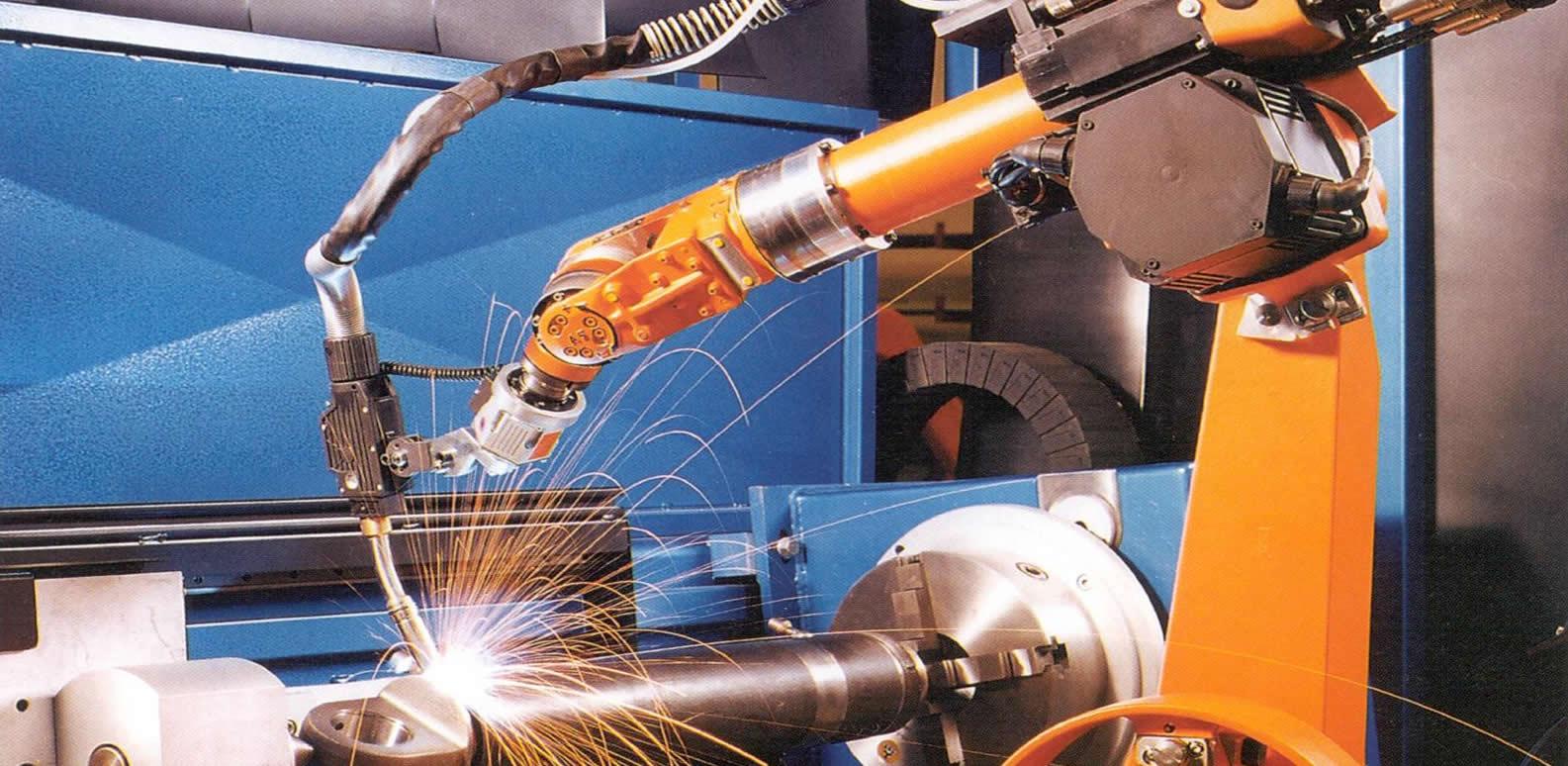

Welding can be a true fine art in itself. https://karenjeff48.bloggersdelight.dk/2023/01/12/linen-metal-fabrication-inside-the-21st-century/ will be the job with the welder to take a pile of cut and formed shapes, study the prints, after that weld the metallic pieces together for the final product. There is some sort of plethora of welded techniques which can be used plus it is important for the welder to use the correct procedure in buy to get a great penetrating weld that wont fail. Welders must know how to deal with the enlargement and shrinking involving metal as this is heated in the course of the welding method, then cools. Many metal fabrications, specifically machine parts, have narrow tolerances that must be met. Fixtures happen to be widely used by simply welders to help them quickly position the pieces together in addition to hold them in the right place while they are welded them together.

Material tubing and barstock is another frequent item purchased simply by metal fabricators. Hand rails and machine support frames are two very common places that metal tubing and bar is used. Lines is made in square, round, or rectangular shapes with a common wall density of about 1/8", referred to by the industry as ten or 11 judge, or schedule 45 pipe. The main reason metallic tubing is commonly applied is because it provides lot strength together with less metal compared to solid bar. Big tubing, 2-4 ins in diameter is used to fabricate hand rails that are mounted along highway bridges where a very strong railing should be used ought to a vehicle collision into it. Using tubing as opposed to solid club translates to much less weight and lower cost, both desired to the user of metal agencement. However, there happen to be still many cases exactly where solid bar is definitely preferred. One situation would be typically the shaft of the screw conveyor. Presently there is extreme pressure applied by a motor to switch the auger in addition to solid metal will be necessary for productive operation of the particular screw conveyor. Many railings are furthermore made of bar stock or made of a variety of bar and tubing. Pub is used in applications where typically the railing doesn't have to be very heavy duty in addition to thinner bars are usually desired. One half to 1 in . bar is traditionally used for railings in the residential and industrial purposes. Metal hand rails when made away of galvanized, decorated, or stainless steel manufacture can be predicted to last the lifetime with almost no maintenance.

Strength, minimal to no servicing. Long lasting. Gowns the regarding metal. That's why a lot of products are manufactured with metal. Steel fabricators hold the devices and understanding of exactly how to take foundation metals that are melted and manufactured by steel industrial facilities, and turn them in to very useful products of which can last the lifetime.